What is the difference between extrusion molding and injection molding of hollow board?

- Share

- Issue Time

- Nov 5,2020

What is the difference between extrusion molding and injection molding of hollow board?

What is the difference between extrusion molding and injection molding of hollow board? Recently, many readers have sent private messages to consult me about this issue. The kindness is difficult. So, the content sharing on hollow boards in this issue will mainly focus on this topic.

#hollow board#

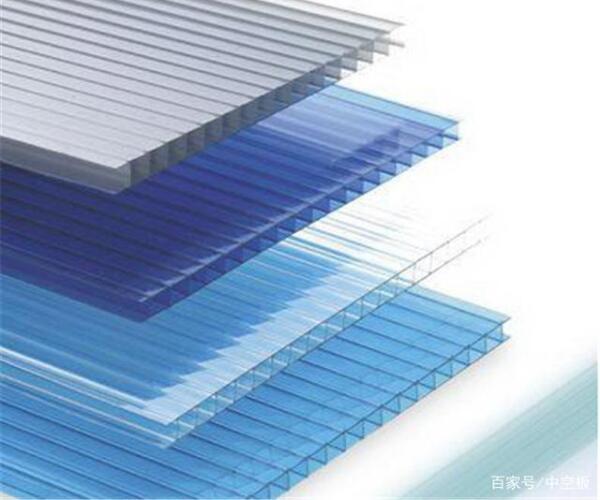

In the current market, our common hollow panels are generally extrusion molded, and injection molded hollow panels are rare. The extruded hollow board allows the raw material to be plasticized between the extruder barrel and the screw while being pushed forward by the screw and continuously passed through the head to make various sections or semi-products. This process technology, the production process is continuous, can extrude any length of hollow board, the productivity is very high, the mold is simple, the size can be accurately grasped, the manufacturing and maintenance are convenient, and it has the advantages of low investment and high efficiency.

In the injection-molded hollow plate, the plastic is heated to a certain temperature by an injection molding machine, the plastic is melted into a liquid, injected into a sealed mold cavity, and molded after cooling.

It can produce all kinds of hollow board products with complicated sound insulation, the molding structure size is more accurate, the surface quality is better, and it can be standardized, standardized, and serialized, but the mold is expensive, the equipment is expensive, and the investment is huge.