Selection of injection machine

- Share

- Issue Time

- Jul 27,2020

Summary

As a guide, generally the injection machine should be selected so that molded product volume will become 30%

to 80% of the machine's injection volume

1.Select by injection volume

As a guide, generally the injection machine should be selected so that molded product volume will become 30% to 80% of the machine's injection volume. When molding, the relation of the machine's injection volume Q(g) and one shot weight (sprue and runner weight included) W(g) should be in the range indicated below.

Q = (1.3~1.5)×W

If the injection volume is too small, plasticization will not make it, and might lose its original physicality as a molded product because the resin will be sent without enough plasticization. On the other hand, if the injection volume is too big, residence time inside the cylinder will be longer and cause degradation by more chance.

2.Select by mold clamping pressure

Both toggle type and direct pressure type is suitable when molding NOVADURAN. The relation of molded product projected area A(cm2) and required mold clamping pressure P(ton) should be in the range indicated below.

P = (0.5~0.7)×A

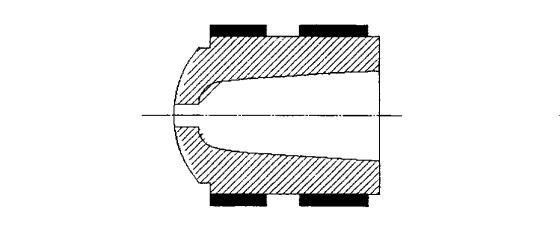

3.Nozzle structure

Open nozzle is common when molding NOVADURAN. The nozzle of commercially-supplied injection machine can be open nozzle or shut-off nozzle (Figure 1-1) but in any type, it is necessary to have a temperature control.

If drooling from the nozzle is concerned, use the shut-off nozzle. However, it might cause burn and sunspot object by resin retention at the slide part, so be careful.

(A) Open nozzle

(B) Shut-off nozzle

4.Injection mechanism

NOVADURAN can be molded by the basic injection machine which has the function of constant injection speed and two-stage injection pressure control, but when molding the product which severe measurement,appearance, and moldability (liquidity and demoldability) is required, it is effective to use the machine that has a program control of injection speed and injection pressure.

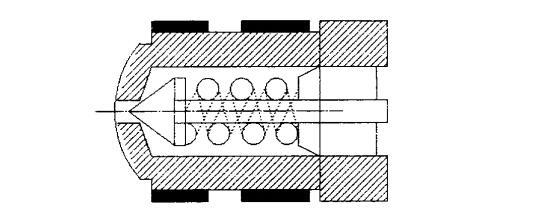

5.Backflow prevention ring

Backflow prevention ring is necessary at the screw, because NOVADURAN has relatively low melt viscosity. If this backflow prevention ring is damaged by wear or corrode, cushion volume cannot be kept because of the resin backflow from the cylinder to the hopper when injecting (pressure keeping), and injection pressure (holding pressure) might not be put properly to the cavity. In this case, good molded product cannot be made, so cushion volume and its stability must be well controlled and maintained when molding. Corrosion and abrasion resistance steel grade is preferable for the back flow prevention ring.

6.Drying machine

Preliminary drying is necessary before molding NOVADURAN, and the condition below is general.

120℃ 5~8 hours

130℃ 4~6 hours

Shelf-type hot air circulation dryer, hopper dryer, or dehumidification dryer is preferred when drying. To prevent the dust and the dirt getting inside, a filter should be placed to air intake of the drying machine, and its maintenance against clogging is also necessary.