Molding operation-Preliminary drying of materials ・Dryer

- Share

- Issue Time

- Aug 5,2020

Summary

These results indicate that the degradation of the impact strength in addition to the generation of defective appearance is very large. Therefore, it is

important to use the dried pellets that the moisture content is lower than the above mentioned limit to have a good performance of Iupilon / NOVAREX.

Since Iupilon / NOVAREX have an ester bond in the main chain, the hydrolysis occurs when heated with the moisture.

As a result, the physical properties, particularly the molecular weight and the impact strength are reduced. Also, the

preliminary drying before molding is necessary because the generation of silver streak and void at the appearance occur.

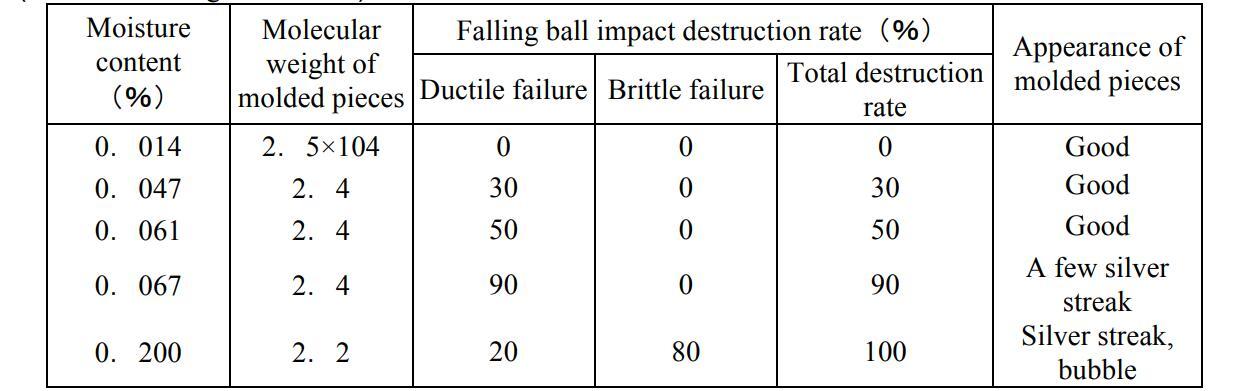

The moisture content in the pellets should be assumed to be 0.015~0.020% at the preliminary drying of Iupilon /

NOVAREX. The results of the molding at various moisture content are shown in Table 2・1-1. These results indicate that

the degradation of the impact strength in addition to the generation of defective appearance is very large. Therefore, it is

important to use the dried pellets that the moisture content is lower than the above mentioned limit to have a good

performance of Iupilon / NOVAREX.

Table 2・1-1

Effect of the moisture content at the time of injection molding

S-2000(Molecular weight 2.5×104)

(Note) Weight of falling ball impact test 2.13kg. The head makes the heavy bob of 10mmR fall from the height of

10 m

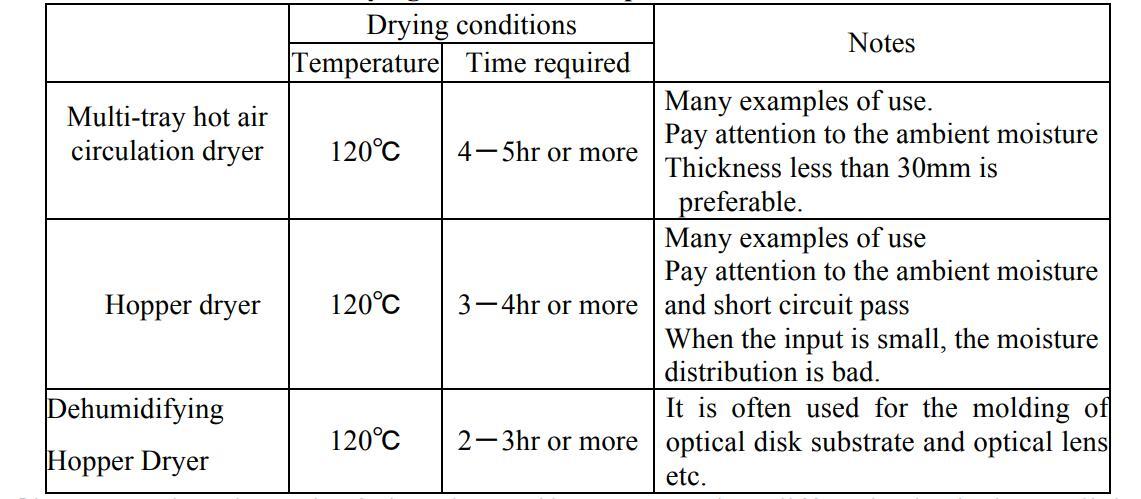

The drying conditions of Iupilon / NOVAREX are indicated in Table 2・1-2

Table 2・1-2

Drying conditions of Iupilon / NOVAREX

(Note) Please note that the grade of the polymer -alloy type sometimes differs in the dry ing conditions.

In order to dry the pellets of Iupilon / NOVAREX until the moisture content is lower than the above mentioned limit、

it is necessary to note the kind of the dryer, its performance and environment ( temperature and moisture).

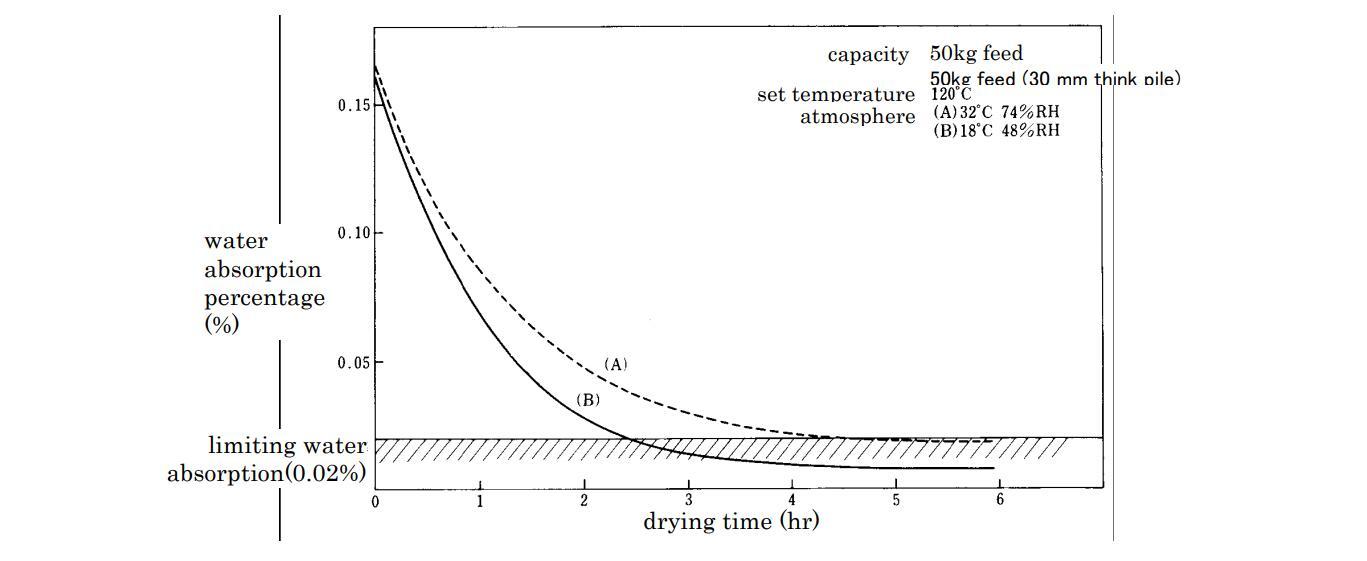

Fig. 2・1-1 is the example which shows the dry curve by the difference of the environment with the multi-tray hot air

circulation dryer. The dry efficiency is decreased under high temperature, high humidity and it requires long time until

the moisture content is lower than the limit.

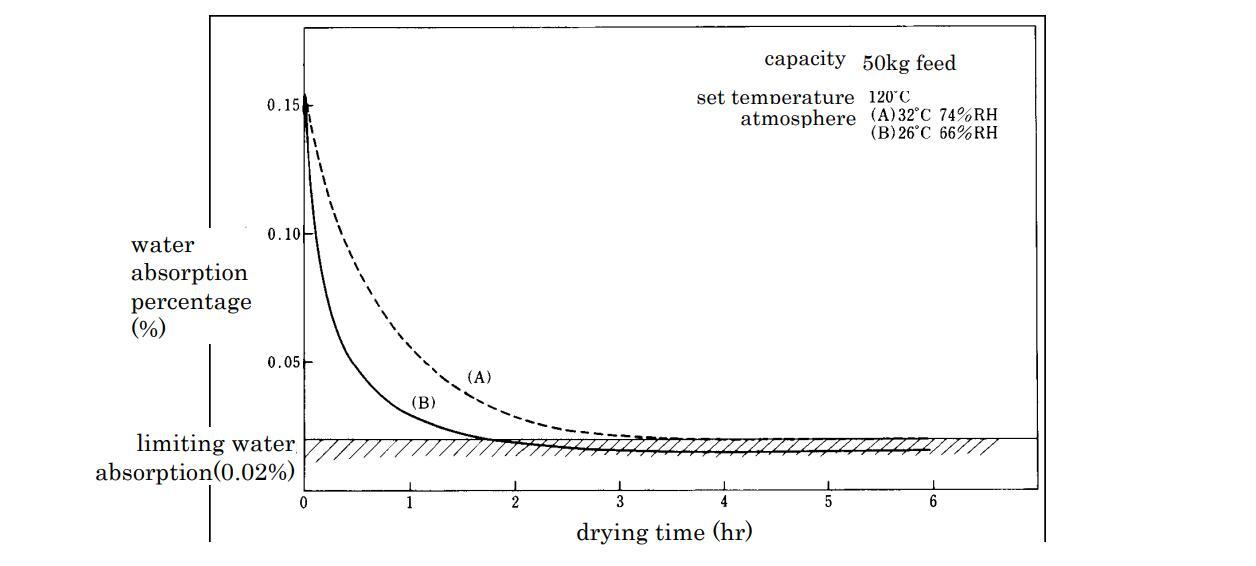

Also, Fig. 2・1-2 shows the results obtained by the hopper dryer in the same way.

The dehumidification hopper dryer that is not affected by the environment and the dry efficiency is good. However, it

is necessary to pay attention to the time degradation of the dehumidifier performance and consider the short pass

phenomenon of the pellets when determining the drying capacity.

Fig. 2・1-1

Multi-tray hot air circulation dryer

Fig. 2・1-2 Drying conditions by the hopper dryer

Prevention of moisture absorption in the hopper

It is necessary to pay attention to the moisture re-absorption in the molding machine hopper in addition to the

preliminary drying of the pellets as described in Section 2・1. Moreover, it is also necessary to consider preventing the

moisture re-absorption by shortening the installation of the hopper dryer, hopper insulation and dwell time of the

pellets as much as possible.