In the case of multi-cavity type, runner design will play an important role

- Share

- Issue Time

- Aug 10,2020

Summary

In the case of multi-cavity type, runner design will play an important role, because the dimension tend to vary widely. Family-cavity type, which molds the product with different cavity shapes simultaneously, is basically not recommended.

In the case of multi-cavity type, runner design will play an important role, because the dimension tend to vary widely. Family-cavity type, which molds the product with different cavity shapes simultaneously, is basically not recommended.

In the case of double-cavity layout, right and left layout is preferred rather than above and bottom, because it will be affected by the gravity. Especially talking about thick molded product, the resin will be affected by the gravity at the lower cavity, and jetting might occur because it droop down to the lower cavity after getting through the gate.

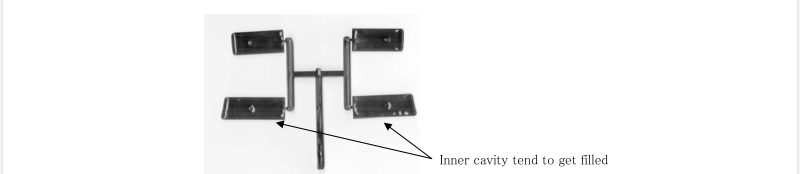

In the case of multi-cavity type, the runner length to each cavity should be laid out equally (isometry runner), and try to fill up simultaneously. If the runner length differs like a serial runner, keep balance by the gate diameter. In the case of more than octuple-cavity type, inner cavity tend to get filled even if the isometry runner is used, so keeping balance by the gate diameter might be necessary (Figure 2-13)

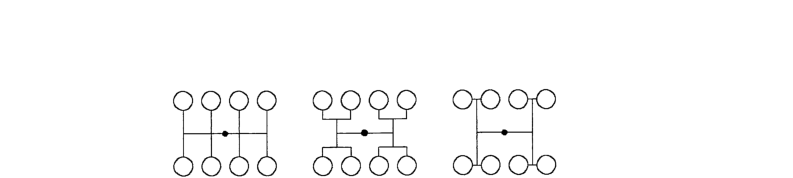

(A) Serial runner (B) Isometry runner (C) Isometry runner

Figure 2-12 Layout example of multi-cavity

Figure 2-13 Filling pattern example of octuple-cavity isometry runner (one side half model)