What should be paid attention to in the process of injection mold manufacturing?

- Share

- Issue Time

- Sep 17,2020

Summary

The reason why injection mold is called the mother of industry is that it can produce plastic products of various shapes. In short, it can be created into various shapes and forms just like the silly putty played by children.But injection mold manufacturing is a fine job.There are a lot of details to look out for

The reason why injection mold is called the mother of industry is that it can produce plastic products of various shapes. In short, it can be created into various shapes and forms just like the silly putty played by children.But injection mold manufacturing is a fine job.There are a lot of details to look out for.So let's see what we need to pay attention to.

1) Avoid sharp corners

I believe that many people will ask why in the process of injection mold manufacturing, to avoid the emergence of sharp corners?In fact, it is not difficult to understand to smooth the surface of plastic products, we must ensure that the production of plastic products used in the injection mold can not exist sharp Angle, so that the production of plastic products can not only look more smooth shape, but also to avoid the appearance of sticky mold and other problems, which is conducive to improve the quality of plastic products.

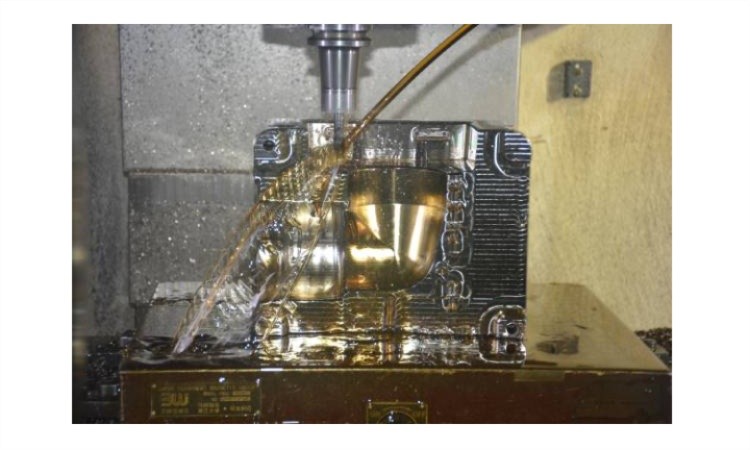

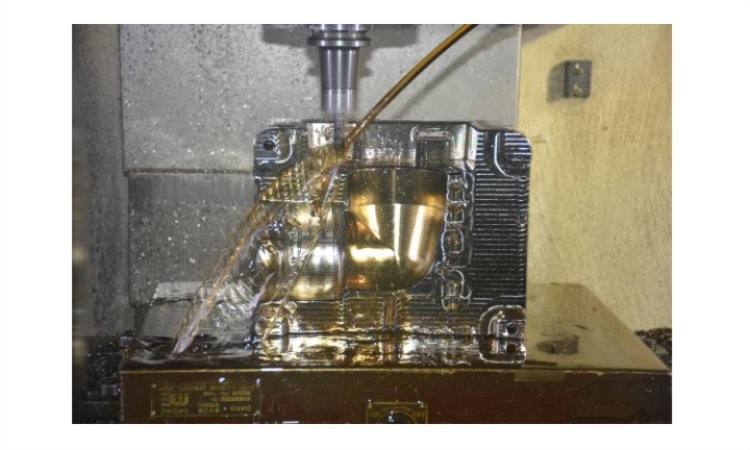

2) Ensure smooth surface of injection mold.

If in the process of injection mold processing and manufacturing, mold surface is not smooth, can affect the surface finish of plastic products, it is easy to cause plastic sticky mold, so it is difficult to ensure the integrity of the product, so in order to avoid the happening of this kind of situation, when in injection mold processing and manufacturing processing of the mold surface of the some as much as possible.

3) The design of vent hole must not be forgotten

Why do injection molds design vents?Because if the injection mold processing and manufacturing of mould sealing do very good, is likely to lead to after the injection of the melt, internal will appear a lot of bubbles and thus also affects the quality of the products, so in order to avoid the emergence of this situation, so in the process of injection mould processing manufacturing must design a vent, the air inside the mold and melt some of bubbles can only be discharged.