industry market status and development trend analysis design and manufacturing intelligent, green development

- Share

- Issue Time

- Sep 29,2020

Summary

In 2020, China's plastic mold industry market status and development trend analysis design and manufacturing intelligent, green development

The global mould industry is more competitive

Although China's plastic mold industry started late, but entered the 21st century, through the continuous improvement of relevant technology and management, has had a rapid development, and now has a considerable scale.Mould has always been called the "mother of industry", and the main countries producing mould in the world have accelerated the pace of overseas expansion, with fierce competition.

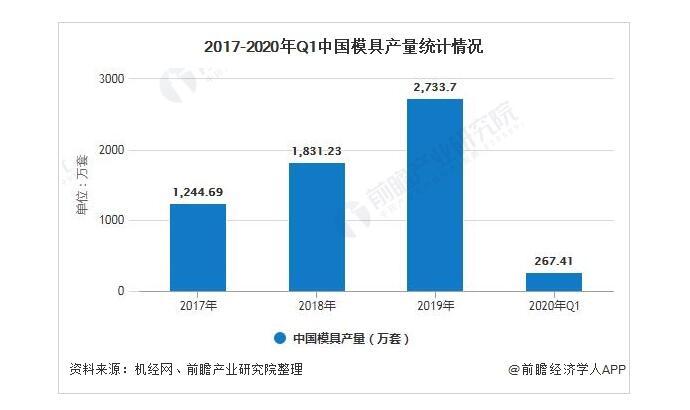

1. China's mold production keeps increasing

Plastic mold, is the plastic processing industry and plastic forming machine matching, give plastic products with a complete configuration and precise size of tools.In the manufacturing process, especially in the industrial production of mechanical parts, all kinds of functional parts have to rely on mold forming.And now more and more production enterprises to use plastic mold parts production and processing, but also for enterprises to reduce the production cost.Therefore, plastic mold in machinery, automobile, home appliances, electronics and other fields more and more widely used.In 2019, China's mold production reached 27.337 million sets, up 49% year-on-year.

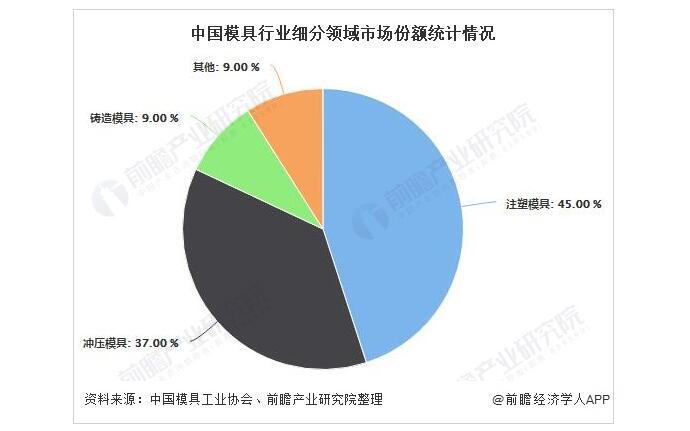

2. Injection mold occupies 45% market share in the mold industry

From the mold industry as a whole, plastic mold and stamping mold is the main segment of the mold market, occupying 45% and 37% market share respectively, accounting for more than 80% in total.

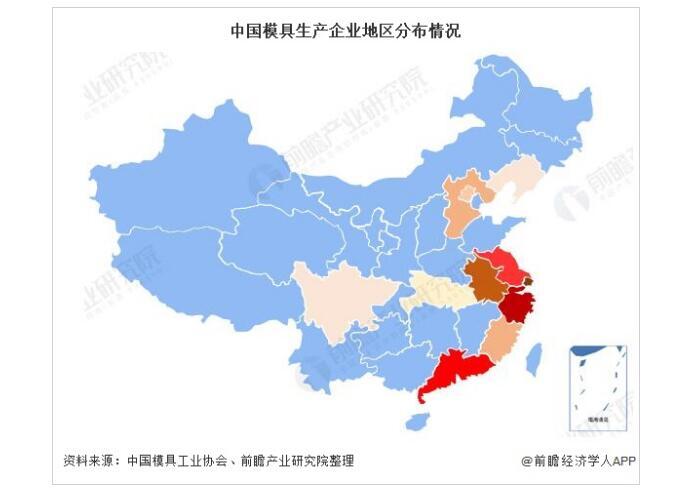

3. China mold industry cluster basically takes shape

Since the beginning of the 21st century, China's mold industry cluster has been basically formed.From the overall layout of the domestic mold industry, the Yangtze River Delta, pearl River Delta, bohai rim region development trend is good.Guangdong, Zhejiang, Shanghai, Suzhou, Anhui and other provinces and cities lead the mold industry in China, and Shenzhen, Ningbo, Suzhou, Taizhou, Qingdao and other cities have become mold enterprises and talent gathering places.These mold backbone enterprises in brand construction, technological innovation, market share, product characteristics and enterprise planning are exemplary, guide the diversified development of mold enterprises around.

4. Domestic plastic molds are constantly replaced by imports

From the perspective of import and export, plastic mold is the largest subdivision product in China's import volume and the largest subdivision product in China's export volume.Since 2014, the import volume of plastic molds in China has been on a downward trend, reaching 872 million US dollars in 2019.At the same time, the export volume is on the rise. In 2019, China's plastic mold export volume reached $3.902 billion, accounting for 62.47% of the mold export volume.Thus it can be seen that domestic high-quality plastic mold has gradually broken through the foreign monopoly, import substitution.

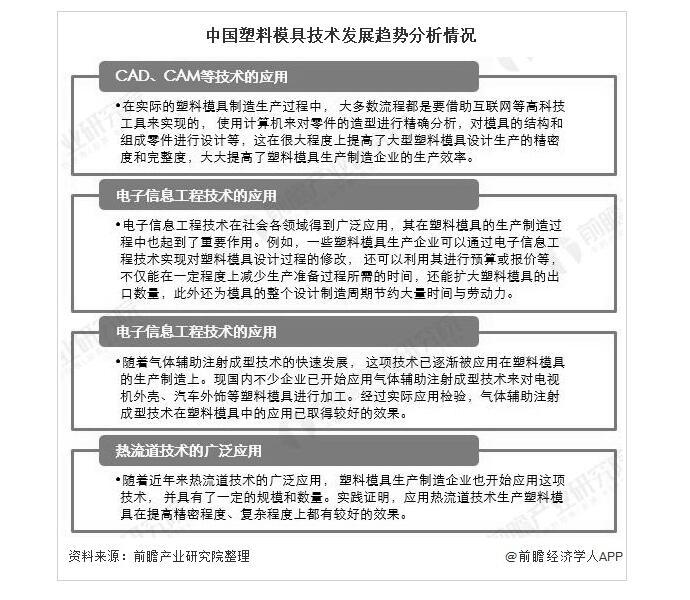

5. Analysis of the development trend of Plastic mold technology in China in the future

China's plastic mold industry development so far, has made rapid progress, plastic mold design and manufacturing technology, CAD and other related technologies in China has been a considerable depth of research.However, modern enterprises need to strengthen the research of plastic mould under the circumstance that the different process conditions used by plastic mould manufacturers lead to the uneven quality of domestic mould.

With the continuous development of modern science and technology, CAD, CAM, CAE and other technologies have been applied in the design and manufacture of modern plastic molds, and have even been widely used, making great contributions to the development of modern plastic mold industry.

In addition, electronic information engineering, gas assisted injection molding, hot runner and other technologies will be more and more widely used in the production of plastic mold.With the continuous improvement of social production requirements and enterprise processing level, the production mode and enterprise concept of plastic mold manufacturing are changing, the product level is gradually improved, the production cycle is getting shorter and shorter, the further improvement of supporting processing capacity, plastic mold design and manufacturing will be more intelligent and green.

For more data and analysis, please refer to the Development Prospect Forecast and Transformation and Upgrading Analysis Report of China's Plastic Mold Industry by Foresight Industry Research Institute. Meanwhile, Foresight Industry Research Institute provides solutions such as big data, industrial planning, industrial declaration, industrial park planning, industrial investment attraction and so on.

(Source: Foresight Industry Research Institute)

(Responsible Editor: DF398)

Solemnly declare: Oriental fortune net publishes this information for the purpose of spreading more information, and has nothing to do with the position of this site.