Why so many customers come to SINO MOULD for the PET preform mould?

- Share

- Issue Time

- Jan 27,2021

Summary

Preform mould cooling is the very important issue, inefficient cooling will cause PET material crystallized under the high temperature, it will reduce the bottle blowing rate. Low quality cooling also will slow down the production speed. In order to realize the long time cooling effect, Sino Mould innovated with a very special design for most effective cooling solutions, also prevented water channel blocking due to the hard water.

Why so many customers come to SINO MOULD for the PET preform mould?

Highlights for PET Preform Mould

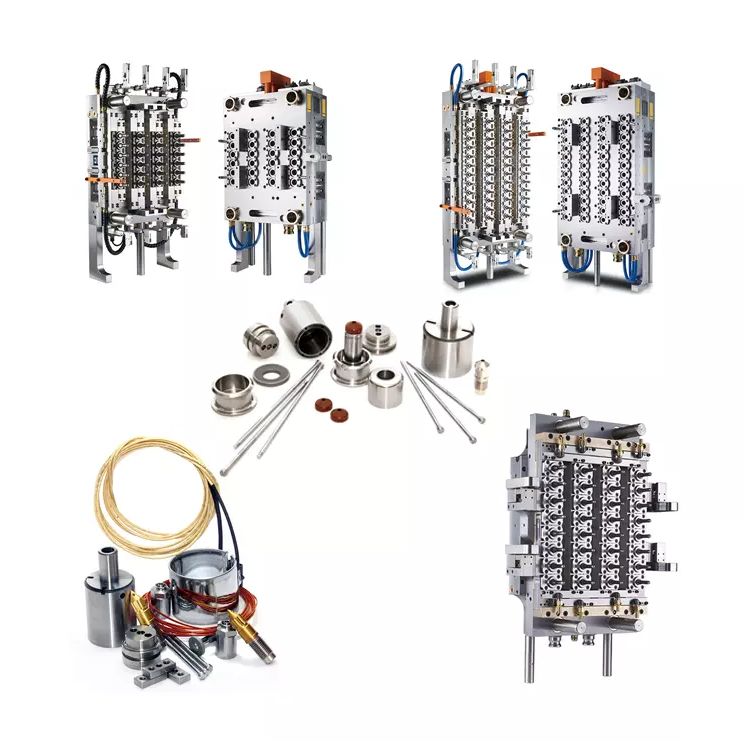

SINO MOULD owns 20 years PET preform mould manufacturing experiences, and always innovates in preform mould design, machining process, hot runner improvements, steel selections… Those years, we keen on PET preform molding faster, more precision and higher bottle blowing rate researching. We made annually more than 200 sets of PET preform moulds, with the cavities Nr. upto 144 cavities.

- Preform Mould Cooling System

Preform mould cooling is the very important issue, inefficient cooling will cause PET material crystallized under the high temperature, it will reduce the bottle blowing rate. Low quality cooling also will slow down the production speed. In order to realize the long time cooling effect, Sino Mould innovated with a very special design for most effective cooling solutions, also prevented water channel blocking due to the hard water.

- Preform Mould Standard Components Stored

Each preform mould we have standard spare parts and components stored. In order to save service time, we delivered the standard parts with the mould. We established Sino Mould Preform Mould Standard and stored series standard components for mould making convenience and quick service purpose.

- A Series Professional Preform Molding Machine

SINO MOULD brother company DAKUMAR has series professional PET preform injection molding machines, which are high speed hybrid high standard molding devices with 3 actions in the same time. We guarantee that you can get the mould with the shortest cycle times & maximum output.

- High Funding Rotation Rate

Select ours PET preform molding line, you can start your facility in the shortest time, for example 4 months you can start mass production. Your investment will be effective in the shortest time. Thus is the very important point for an investor, because TIME is market, TIME is money, Time is everything… With the shorter production cycle time, you can get the profit at the fastest speed which can better help you get the funds flow.