Plastic injection mold to choose a mold cavity advantages

- Share

- Issue Time

- Oct 12,2020

Summary

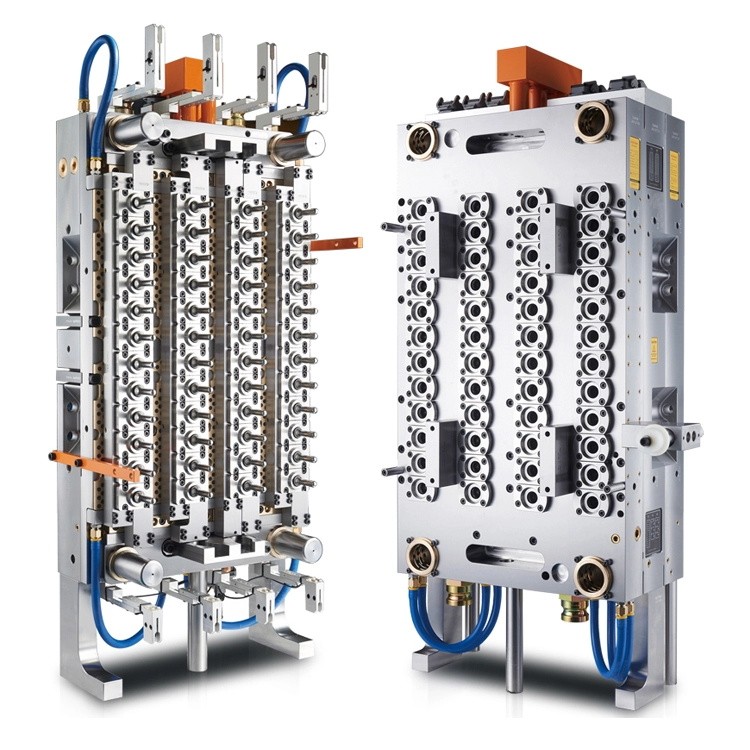

What are the advantages of multi-cavity mold?In order to increase the productivity and reduce the pouring loss of the passage, multi - cavity molds can be used to finish many same or different products simultaneously within one mold

Generally, the design of one mold and two cavities is mainly based on the following injection molding capacity consideration, and the individual is also based on the product structure or mold structure consideration.Therefore, its outstanding advantages are as follows :1. It can greatly improve the production capacity of injection molding products. According to personal experience, it can generally increase the production capacity by 60-80% (relative to 1*1 mold), reduce the production cost and improve the production efficiency; 2.2. Due to the structural problems of the product (such as the small structure of the plastic parts), design 1*2, which can smoothly remove the glue and improve the quality of the plastic parts during the product injection.In fact, at present, there are more 1*2 molds in the mobile phone shell industry, while 1*4 molds are very few, mainly because of the number of holes, injection molding is the problem point is more, so I want to say to you, not the number of holes is the better, is a degree (under the current technical conditions).

What is the advantage of multiple cavities in a mold for single opening or squeezed together opening of multiple molds is usually used in two situations :1) Large batches of products, multiple cavities in a mold can produce multiple parts in a single injection cycle, thus improving the efficiency.At this point, can decorate the multiple parts in a mold production at the same time. 3) the cavity must be on the overall force balance in the state, otherwise easily lead to abnormal wear of the plastic injection machine. (4) pay attention to the balance of the runner gating system, the runner and gate control. 5) more than a mold cavity more complicated than the single cavity mould manufacturing, manufacturing increase with the increase of the price will be according to the number of cavity

What are the advantages of multi-cavity mold?In order to increase the productivity and reduce the pouring loss of the passage, multi - cavity molds can be used to finish many same or different products simultaneously within one mold

There are two forming cavities in a mold. Two parts can be produced in one injection cycle, which is more efficient than single mold cavity.Die cavity, also known as cavity.Is the cavity of the mold. The space in which plastic products are formed in the mold.A space to hold the binder and the injection binder.Mu Ju, industrial production for injection molding, blow molding, extrusion, die casting or forging into...

A mold a few cavity and a mold a few is the same concept?"A mold a few" is refers to "a mold a few cavity" or "a mold a few"?A: V. is not a concept. A mold of several cavities means that there are several molded cavities, which may be one piece. A mold of several pieces means that several pieces are formed and produced at a time, and a mold of several pieces is what is meant by this

In a multi-cavity mold, what should be done to prevent the front cold plastic from blocking during injection?Increase the mold temperature, increase the diameter of the flow passage and increase the cold material well.As the number of cavities increases, the length of the channel also increases.The temperature of plasticized raw materials will gradually decrease when they enter the mold cavity through the spout sleeve, main channel and shunt channel, and it may even appear that the material temperature is too low to inject the mold cavity.Knowing the reason, we can take measures to deal with it...

The correct number of cavities shall be determined according to the capacity and product structure. The more cavities, the higher the precision, processing difficulty and the cost of the mold.But the unit price of injection parts will drop significantly.Factors influencing the size of multi-cavity products :1. Precision of mold processing.For example, the cavity discharge, each cavity is a discharge, if the discharge process control is not good,...

The method for filling all types of plastic at the same time is masterCAM: round with streamline or surround, square with radiation or contour, irregular with machining range in four parts with parallel 45 degrees and 135 degrees Angle

Is the number of mold cavities the more the better?The answer is, of course, no.The number of injection mold cavities is related to the molding capacity, maximum injection volume, and clamping force of the injection molding machine. Manufacturers of custom molds should select the number of injection mold cavities based on the maximum injection volume and rated clamping force of the existing injection molding machine.According to the maximum injection volume of injection molding machine to determine the number of cavity N≤(...

Advantages and Disadvantages of the hot runner Mold the advantages of the hot runner technology Save plastic raw materials because there is no condensing material in the hot runner.Or very small cold handle, basically no cold runner gate material need not be recycled, especially expensive, can not be used to process plastic products, can greatly save costs.Application of hot runner if the normal production of the general 2-3 months, you can recover the cost of hot runner.