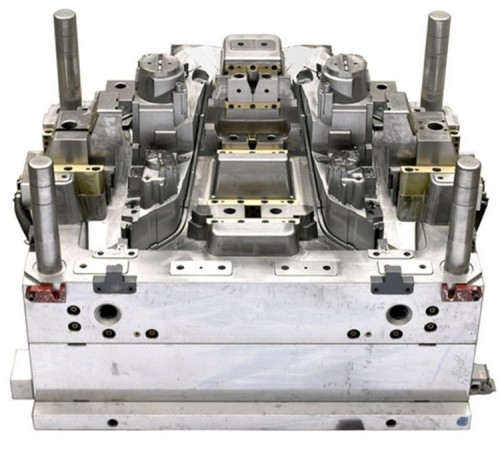

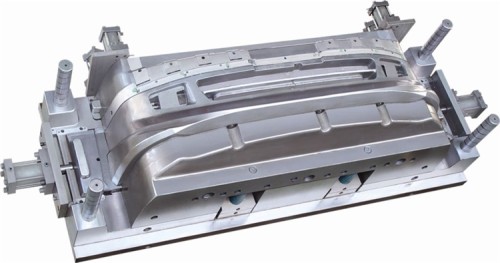

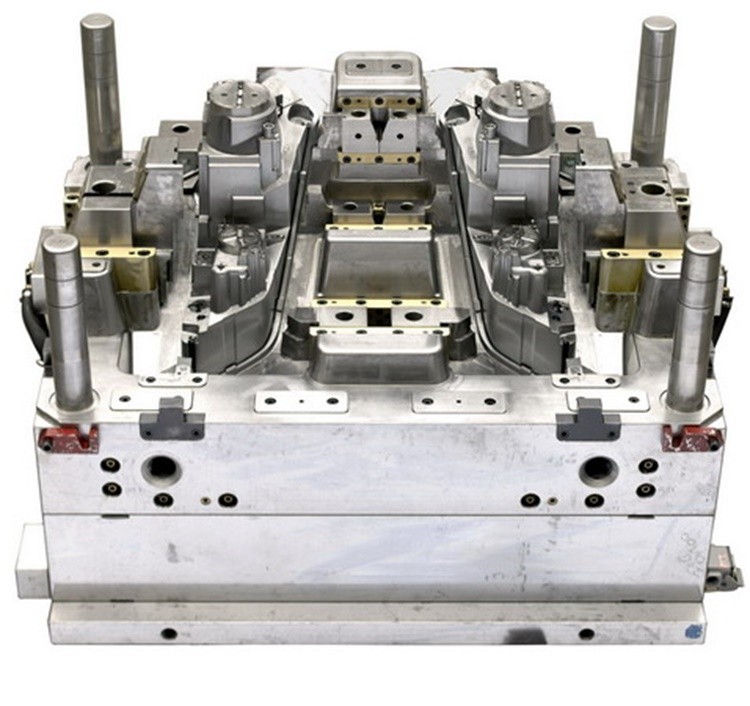

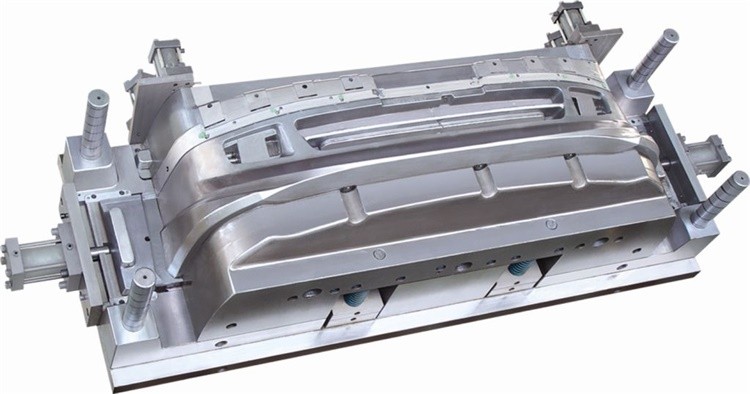

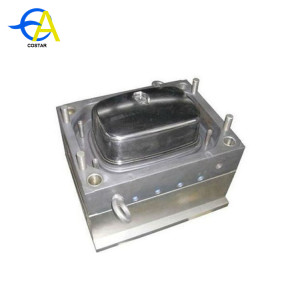

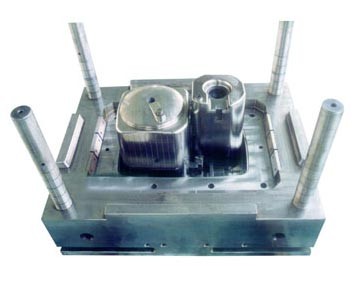

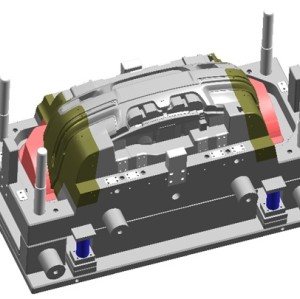

China factory design injection bumper plastic auto mold,auto parts mold

- Model

- OEM

Item specifics

- Cavity/Core Material

- 718H, P20, NAK80, 2316, 2738, 2344

- Base

- LKM or by requested

- Runner System

- Hot runner, Cold runner

- Cavity

- Single cavity, multi cavities by requested (support similar products in one mould)

- Finish

- Corrosion word, Mirror finish, Brushed

- Software

- CAD, Pro-E, UG, etc

Review

Description

Place of Origin: | Jiangsu, China | Cavity/Core Material: | 718H, P20, NAK80, 2316, 2738, 2344 |

Product Material: | ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA, PBT, PEI, etc., Steel | Longevity: | Available SHOTS will depend on the steel material you choose |

Runner System: | Hot runner, Cold runner | Cavity: | Single cavity, multi cavities by requested |

Finish: | Corrosion word, Mirror finish, Brushed | Base: | LKM or by requested |

Mould standard: | HASCO, DME, MISUMI, or by requested etc. | Software: | CAD, Pro-E, UG, etc |

Main Technique: | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. | Shaping Mode: | Plastic Injection Mould |

Product: | Household Product |

Machine Feature:

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication, provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.